Content Hub

Content

Select model below to download media assets

Overview

The new Continental GT Speed is the most dynamic road car in Bentley’s 101 year history and the ultimate performance-focused interpretation of the world’s benchmark luxury Grand Tourer.

Designed, engineered, developed and handcrafted in Bentley’s carbon neutral luxury automotive factory, this new third-generation model builds on a long tradition of Speed variants. Originally introduced with the highly-acclaimed, first generation Continental GT Speed in 2007 – itself inspired by the 3-Litre Speed models of the 1920s. The latest GT Speed continues the bloodline by representing the ultimate combination of luxury and performance in a Grand Touring package.

Dr. Matthias Rabe, Member of the Board for Engineering at Bentley Motors, comments:

“The new Continental GT Speed represents the very pinnacle of performance grand touring. This new model is the most powerful expression of Continental GT values, exciting and dynamic, with unique Speed detailing to enhance the ownership experience and offering customers more control over the character of the car.

“The world’s most luxurious Grand Tourer is now truly more capable than ever before, with a new sportier edge which will appeal to performance-focused drivers. The Speed is the latest chapter in the Continental GT story, helping Bentley customers to create their own extraordinary journeys.”

The pinnacle performance Continental GT features advanced chassis technology harnessed specifically for the new model.

New Electronic All-Wheel Steering enhances the dynamic nature of the Speed in BENTLEY and COMFORT driving modes. However, this is even more apparent in SPORT mode, as the steering combines with Bentley Dynamic Ride and an electronic limited slip differential for a level of agility unlike any other Bentley road car. Specifically tuned hand-in-hand with the traction control and active chassis systems, the eLSD provides increased lateral capacity, improved longitudinal stability, enhanced on-throttle adjustability and delivers better traction in adverse road conditions.

Featuring Active All-Wheel drive, the traction control and torque distribution has been recalibrated in all driver modes to provide a noticeable character shift relative to the standard Continental GT.

The new GT Speed is the ultimate performance-focused expression of Bentley’s definitive Grand Tourer, yet maintains the luxury, comfort and usability of its siblings. It is equipped with an uprated version of Bentley’s renowned 6.0-litre W12 TSI engine, delivering 659 PS (650 bhp) – a 4 per cent increase of 24 PS over the current W12 model – whilst maintaining an extraordinary 900 Nm (664 lb.ft) of torque. With exceptional handling, this results in a top speed of 208 mph (335 km/h) and 0-60 mph in 3.5 seconds (0-100 km/h in 3.6 seconds), a reduction of 0.1 second.

Speed models add a Dark Tint radiator grille and lower bumper grille, as well as unique, more sculpted sports sills, a Dark Tint radiator matrix and discreet Speed badging in chrome on the front fender.

Another signature feature of the most potent version of the Continental GT is unique, 22” Speed wheels in bright silver, with the option of a dark tint or black gloss finish. “Jewel” versions of the fuel and oil filler caps are standard, while illuminated Bentley treadplates to both sills are a nod to the Speed’s performance credentials.

The GT Speed coupe is joined by its sibling Convertible, which uses a unique Z-fold convertible roof system - the most advanced of its kind. The roof, with its sealing system improvements and acoustic treatments, contributes to a three-decibel reduction in overall noise levels compared to its predecessor at typical cruising speeds. An entirely new combination of roof insulating materials and operating mechanism, combined with sealing system improvements and acoustic treatments, create a Convertible Grand Tourer that is as quiet as the previous generation Continental GT Coupe.

Chassis Technology

The new Continental GT Speed Coupe and Convertible represents the very pinnacle of performance grand touring, and defines the most dynamic road-going Bentley ever made, with no compromise to comfort or luxury. A combination of four chassis technologies give the Continental GT Speed a level of agility, performance and ride quality that has been stretched to new levels.

Bentley Dynamic Ride and three-chamber air suspension with adaptive damping play key roles in the balance of the car and provide a formidable foundation to build upon. The optional and newly-developed Carbon Ceramic Brakes, Variable Electronic Stability Control, All Wheel Steering, and an Electronic Limited Slip Differential bolster the agility and performance even further.

Combining the new systems the Continental GT Speed still maintains Bentley’s philosophy that a vehicle should feel progressive and secure, yet still be dynamic.

To achieve this philosophy in BENTLEY and COMFORT mode, overall grip is balanced between the front and rear wheels, while in SPORT this mode has been calibrated with a more rear-biased torque–split in all driving scenarios.

The Largest Car Brakes in the World

The new carbon ceramic braking system boasts 440mm diameter front discs combined with new ten-piston front calipers, making this not only the biggest brake ever fitted to a Bentley but also the largest car brake in the world. This latest generation of carbon-ceramic disc has been specially formulated to provide class-leading braking performance with copper-free brake friction material for reduced environmental impact.

The new ceramic brake system offers weight saving of 33 kg compared to the iron braking system, and most importantly this is un-sprung weight which lowers inertia and gives the vehicle more responsive handling.

The ceramic brake has been extensively tested around the world including at the Nurburgring Nordschleife where it set levels of braking performance never before achieved by a Bentley. In objective tests the ceramic brake has proven itself to be exceptionally fade resistant – after ten consecutive from 80 mph, the stopping distance only increased by 1.1 metres, to just 61.1 metres.

Variable Electronic Stability Control

The Electronic Stability Control (ESC) system allows the driver to experience an even greater level of freedom before the GT Speed’s safety systems intervene to correct any anomalies. With the ESC system engaged, the car provides reassuring stability over uneven surfaces, abnormal cambers or in inclement weather conditions. When switched to Dynamic mode, the ESC system extends the freedom of the driver, allowing the experienced pilot to set and alter the cornering stance of the car at their discretion.

With the ESC switched off, the mechanical grip and inherent balance of the GT Speed comes to the fore, allowing a driver-focused experience previously only seen in Bentley’s racing machines. After utilising strong turn-in performance thanks to the All-Wheel Steering and eLSD, on track the driver can choose to balance throttle and steering to deliver effortless, progressive yaw angles.

All-Wheel Steering

New Electronic All-Wheel Steering enhances the dynamic nature of the Speed in each of the driving modes. This is even more apparent in SPORT mode, as the steering combines with Bentley Dynamic Ride and the electronic limited slip differential for a level of agility unlike any other Bentley road car, utilising up to 4° of steering lock on the rear wheels.

At low and medium speeds, the GT Speed’s rear wheels are steered in the opposite direction to the front wheels to aid a rapid change of direction, noticeably increasing the feeling of nimbleness. The steering feels sharper and with a quicker ratio, and a commensurate increase in steering feel provides even more driver confidence. At high speeds, the rear wheels steer in the same direction as the front, to improve stability. The system is significantly more active on the GT Speed than it is on the Flying Spur, where its primary purpose is a reduction in turning circle and enhanced high-speed stability.

Electronic Limited Slip Differential

For the first time in a Bentley, the latest generation of the Continental GT Speed introduces the use of an electronic limited slip differential (eLSD).

Specifically tuned hand-in-hand with the traction control and active chassis systems, the eLSD provides increased lateral capacity, improved longitudinal stability, enhanced on-throttle adjustability and delivers better traction in adverse road conditions.

In all modes this provides improved traction, provides a greater level of confidence for the driver and makes the vehicle feel more stable at high speeds. In SPORT mode, the eLSD has been tuned to balance on- and off-throttle adjustability, improved turn-in response and increased straight-line performance. The combined benefit means the Continental GT Speed is now more adjustable and more driver-focused than ever before without compromising comfort or stability.

Improved cornering dynamics and the extra grip provided by the new systems allows the driver to exit any corner with an increased level of precision and confidence. In turn, the vehicle is able to extract the maximum performance from the available traction to deliver stunning acceleration and composure from the apex.

Torque distribution can vary across the powertrain according to the selected Drive Mode. In COMFORT and BENTLEY, the system can send up to 36% of torque to the front axle to keep the car sure-footed and effortless. It will also counter oversteer by applying up to 400 Nm to the front wheels.

In SPORT mode, the system limits the available torque to the front axles to 28%, to maintain a higher torque level at the rear axle and allow for a more dynamic feel. The system also responds very differently to oversteer, only sending approximately a 1/10th of the torque to counter as Bentley Mode, providing an increased performance feel.

Powertrain

The new GT Speed is the ultimate performance-focused expression of Bentley’s definitive Grand Tourer, yet maintains the luxury, comfort and usability of its siblings. It is equipped with an uprated version of Bentley’s renowned 6.0-litre W12 TSI engine, delivering 659 PS (650 bhp) – a 4 per cent increase of 24 PS over the current W12 model – whilst maintaining an extraordinary 900 Nm (664 lb.ft) of torque. With exceptional handling, this results in a top speed of 208 mph (335 km/h) and 0-60 mph in 3.5 seconds (0-100 km/h in 3.6 seconds), a reduction of 0.1 second.

Both engine and transmission have been deliberately calibrated to suit the car’s driver-focused credentials. This is most noticeable in SPORT mode, where the twin-turbocharged W12 has been tuned to keep the engine in the power band longer by up-shifting later, or downshifting earlier. This creates a more eager response to the driver’s throttle inputs.

The dual-clutch, eight-speed transmission shift is twice as fast in SPORT mode as in the standard W12 model, in keeping with the Speed’s ethos. This combines with a greater exhaust character during start-up and downshifts.

Not only does the Continental GT Speed offer impressive performance, to maximise efficiency the model benefits from Bentley’s Stop-Start technology where the engine rests not only when the vehicle is stationary, but also at near-to-stop speeds.

Bentley’s Variable Displacement system shuts down half of the engine under defined conditions. Intake and exhaust valves, fuel injection and ignition are all shut down on defined cylinders, with the engine running as a six-cylinder for improved efficiency. The system will run in this mode in gears three to eight, below 3,000 rpm and up to 300 Nm torque output.

Bentley’s legendary 6.0-litre twin-turbocharged W12, created in 2002, has evolved into the latest iteration of W12 engine used across today’s current model range. The unique W-configuration means that the engine is 24 per cent shorter than an equivalent V12, benefitting packaging and maximising usable cabin space. The latest generation of W12 was launched in the Bentayga in 2016. A thoroughly reworked engine included a crankcase 30 per cent stronger than its predecessor, while the cylinder surfaces were coated to reduce friction and improve corrosion resistance. A low-alloy steel coating is applied to the bores using an Atmospheric Plasma Spray (APS) process.

Improvements were also made to the cooling system, with the engine featuring three separate coolant circuits. The first is designed to bring the cylinder heads up to optimum operating temperature as quickly as possible for best engine performance and low emissions. The second cools the engine block and oil system, while the third handles the thermal load of the turbochargers. Each system has a dedicated water pump, allowing optimised individual control. The W12 combines high-pressure direct fuel injection (200 bar injection pressure) with low-pressure port injection (six bar). The combination of these two systems maximises refinement, lowers particulate emissions and optimises power and torque delivery.

Twin-scroll turbochargers minimise turbo response time and provide a more efficient exhaust package. The exhaust assemblies for the three front and three rear cylinders are separate from one another which then feed the twin-scroll impellers. The turbocharger housing is welded directly to the exhaust manifolds and feature integrated speed sensors, allowing the engine to monitor turbo performance for maximum efficiency.

Since the first introduction of the twin-turbocharger W12 in 2003, the refinement of the engine has seen an increase of up to 27 per cent in power, 38 per cent in torque and a reduction of 28 per cent in emissions. This has been realised through evolution and optimisation of the crankcase, improvements in the oil and cooling systems, twin-scroll turbocharging technology and more effective injection and combustion processes.

Each W12 engine is hand-built over 6.5 hours by a team of 45 craftspeople before undertaking a highly sophisticated test regime of over an hour via three specialist diagnostic machines during the engines assemble. The testing not only provides feedback on the quality of each engine but also provides multiple checkpoints to catalogue the exact behaviour of each engine from the moment of manufacture.

The first test is for leakage and can be undertaken after the engine has been assembled to the point that fuel, water and oil systems can be closed – a production stage known as a “short engine”.

The leakage test is conducted by pressurising each of the systems, for fuel, oil and water individually. The different cavities are pressurised to values between 0.2 – 5.0 bar respectively and then measured whilst the pressure decays over time. The reduction in pressure versus time represents the quality of the sealing of the engine assembly. If the pressure drops faster than expected, a leak is indicated. A fluid is sprayed on to the exterior of the engine to pin-point any leakage paths.

The second and most advanced test is Cold Test. The engine is loaded on to a testbed plate and connections are made to the engine loom and all engine systems, whilst a large electric motor couples to the engine via the crankshaft. “Motoring” the engine via the crankshaft allows the test bed to collect data from a suite of sensors. The facility measures 600 individual properties and characteristics of the engine during a 15-minute cycle.

Due to the low running speed of 120 RPM for the test, finer details and any inconsistencies can be identified thanks to a sample rate that highlights even the briefest of anomalies that would be invisible if the engine was firing or running at speed.

This fine detail analysis is also valuable for confirming the precise timing of the engine. Using positioning information from sensors on the crankshaft, crankcase and camshafts along with cylinder compression values, the Cold Test can confirm the engine timing is accurate and therefore achieving the best possible combustion cycle.

In order to gather cylinder-specific data, Cold Test is carried out before the exhaust manifolds, turbochargers and other ancillaries are fitted. The third and final test - Hot Test - checks the complete engine assembly once these parts are installed, and simulates real world usage in the vehicle.

When the engine arrives for hot testing, a UV dye is added to the engine to help identify any leaks. The coolant and fuel system are pressurised with air and nitrogen respectively for a final check before introducing the necessary fluids ready for testing. The engine is cranked to build oil pressure before the ignition system is energised and then left to idle whilst the engine test technician listens for any refinement issues and checks for leaks with a UV lamp.

Each W12 is then tested for a minimum of 21.5 minutes and runs up to 3,800 rpm with a maximum load of 300 Nm. One in every one hundred engines receives a full eight-hour power test, achieving 6,000 RPM, and must achieve 900Nm.

Since the installation of the three testbeds in 2002, over 100,000 W12 engines have been handcrafted in Crewe and passed through the test facility.

Styling

The muscular bodywork of the Continental GT has been amplified further for the GT Speed. Unique exterior detailing complements a powerful, athletic stance, blending seamlessly with the effortless elegance inherent to the Continental GT.

Speed models add a Dark Tint radiator grille and lower bumper grille, as well as unique, more sculpted sports sills and discreet Speed badging in chrome on the front fender.

Another signature feature of the most potent version of the Continental GT is unique, 22” Speed wheels in bright silver, with the option of a dark tint or black gloss finish. “Jewel” versions of the fuel and oil filler caps are standard, while illuminated Bentley treadplates to both sills are a nod to the Speed’s performance credentials.

The cabin of the new Continental GT Speed showcases Bentley’s expertise in creating the world’s finest automotive interiors. Handcrafted materials blend with unique trim and badging that are only available in the Speed and can be further personalised if desired.

The Continental GT Speed’s credentials are further highlighted by a unique duotone colour split handcrafted in hide and matching Alcantara, which is also applied to the steering wheel. The exterior badging is matched with an elegant Speed icon on the passenger fascia.

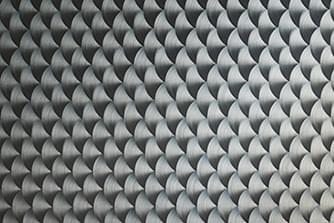

The luxurious interior can be further personalised with a choice of 15 main and 11 secondary hide colours, as well as the use of leather in lieu of Alcantara for the Speed colour split. The centre console can be finished in new dark tint engine turned aluminium, bringing a geometrically perfect machined surface and a beautifully patterned finish.

Bentley’s Diamond in Diamond quilting is included as standard, and Speed embroidered headrests distinguish the cabin of the most potent Continental GT.

A range of veneers are available in GT Speed, starting with Piano Black veneer as standard. Customers can also choose Crown Cut Walnut, Dark Stained Burr Walnut and Dark Fiddleback Eucalyptus at no extra cost, with three open pore options (Dark Burr Walnut, Crown Cut Walnut and Koa) available as additional options.

As with all Continental GTs, the Speed offers four seats and exceptional grand touring luggage capacity of 358 litres. Packed with exquisite detail, a technologically advanced instrument panel and the acclaimed Bentley Rotating Display, the new driver-focused model widens the Continental GT’s performance credentials.

For the GT Speed Convertible, seven exterior roof colours are available, including a contemporary interpretation of traditional British tweed. Black, Blue, Claret and Grey are among the other options. Furthermore, eight interior roof liner finishes are offered, ranging from New Red to Magnolia.